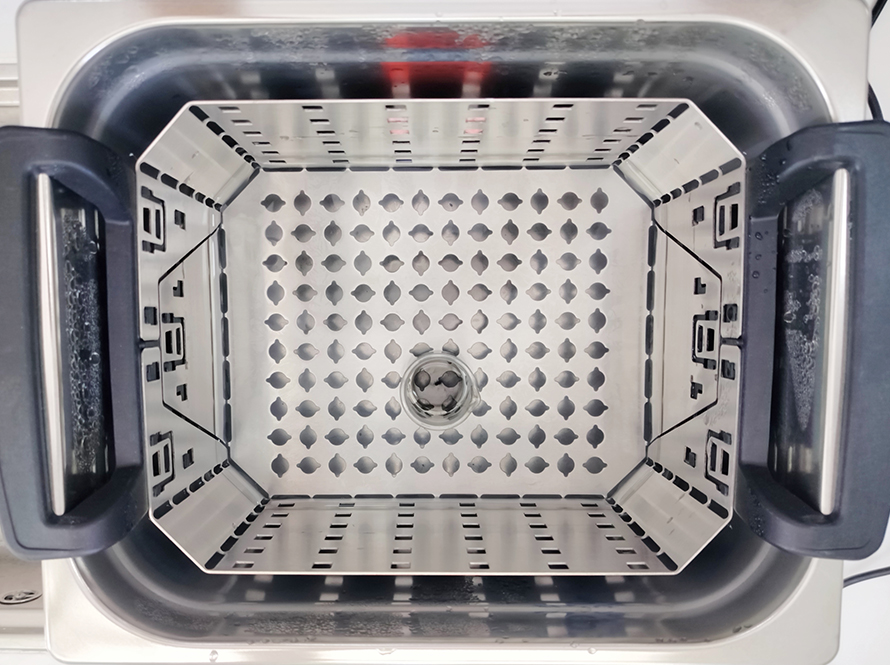

Ultrasonic cleaning is a method of cleaning that uses ultrasonic waves. This technique operates by generating high-frequency sound waves in a liquid medium (usually water or specialized cleaning solutions). Here is a breakdown of the basic working principle and advantages of ultrasonic cleaning:

Working Principle

- Ultrasonic Wave Generation: An ultrasonic generator converts electrical energy into high-frequency sound waves. These waves typically operate at a frequency between 20 kHz and 40 kHz.

- Cavitation: These sound waves create rapidly expanding and collapsing microbubbles within the cleaning liquid. This phenomenon is known as cavitation.

- Microjets: When the bubbles collapse, they produce small, powerful liquid streams called microjets. These microjets effectively dislodge dirt and contaminants from the surface to be cleaned.

Advantages

- Deep Cleaning: Ultrasonic waves can reach microcavities and complex shapes that the cleaning liquid alone cannot.

- Gentle Cleaning: This method can be used on delicate parts because the microjets do not scratch or damage surfaces.

- Speed and Efficiency: It is faster and more efficient compared to traditional cleaning methods.

- Versatility: It is effective on various materials such as metal, plastic, glass, and ceramic.

Applications

- Industrial Cleaning: Used for cleaning industrial components like engine parts, gearboxes, and bearings.

- Medical and Laboratory: Utilized for sterilizing surgical instruments, laboratory equipment, and delicate devices.

- Electronics: Employed for cleaning circuit boards and other electronic components.

- Jewelry: Used for cleaning gold, silver, and gemstones.

Ultrasonic cleaning is a widely used method due to its effectiveness and gentleness in a variety of applications.