Advanced Cleaning Solutions for High Volume Applications

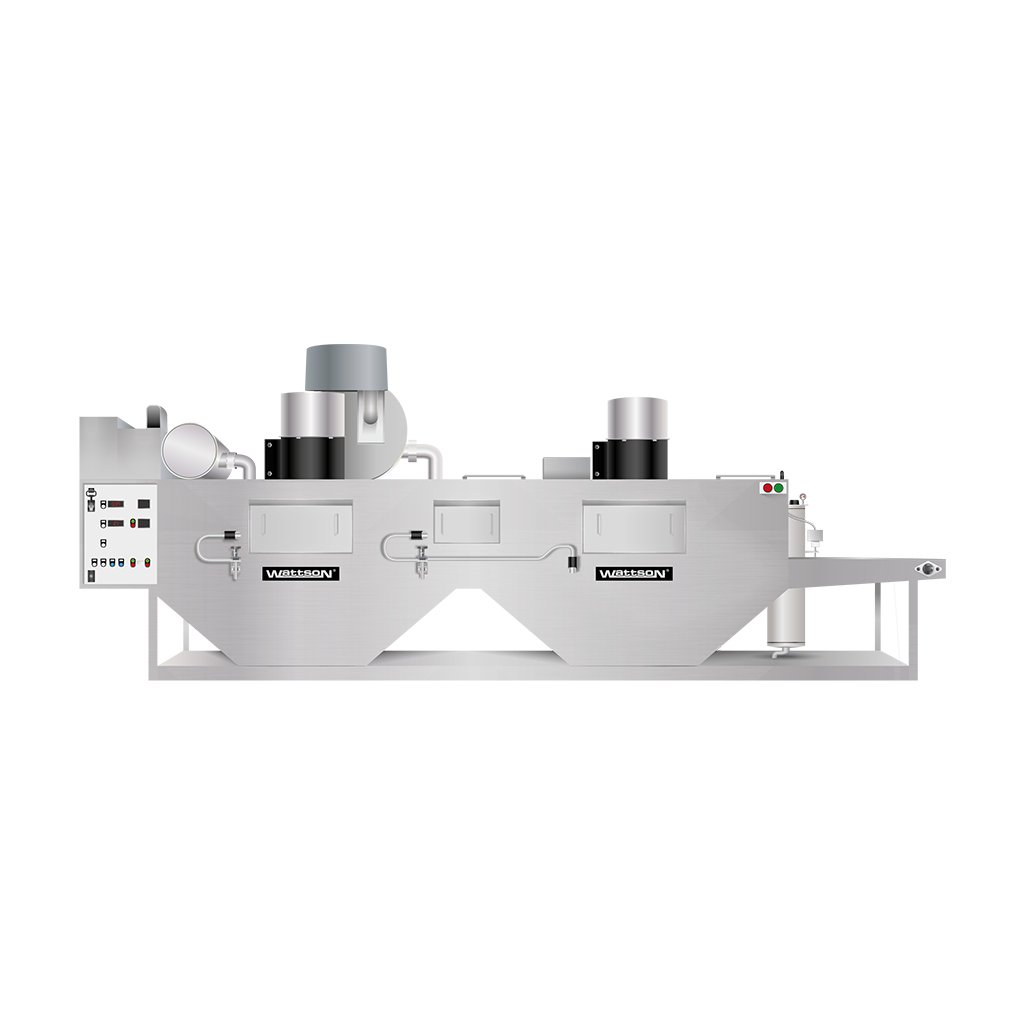

The WTS-K Series Tunnel Washing Machines are designed to optimize the cleaning process in high-production environments by performing multiple station functions within a single machine. Parts placed in the machine's entry chamber are transported without manual handling through the conveyor belt, undergoing washing, rust removal, rinsing, phosphating, passivation (protection against corrosion effects such as rust, tarnishing, and calcification), drying, and similar processes before reaching the exit section.

Manufactured from specially designed stainless steel (304 or 316 quality standard), the conveyor offers the ability to operate at a wide range of speeds through a digital control panel. This series features high carrying capacity and uses imported stainless steel pumps in its circulation systems. The heating system can be electric, heat exchanger-based, or burner-based, depending on preference. To enhance energy efficiency, the boilers and upper body are covered with quality insulation materials. Our systems with PLC can be controlled from the operator panel of the facility. Each machine is equipped with standard safety systems, such as automatic water supply and liquid level control.

Key Features

- Robust Stainless Steel Body: Designed for durability and longevity.

- Stainless Steel Pump: Provides high performance and resistance to corrosion.

- Temperature Control: Adjustable for precise temperature settings.

- Precision Filtration: Maintains the quality of the cleaning solution.

- Steam Ventilation Unit: Provides effective steam management for optimal operation.

- Speed Control: Flexible operation to accommodate various cleaning tasks.

- Emergency Stop Button: Enhances safety during operation.

- Heat Insulation: Saves energy for efficient performance.

Usage Areas

The WTS-K Series is particularly effective in cleaning parts with high production speed or quantities and is used in the following industries:

• Automotive Industry • Coating Industry • Defense Industry • Electronics Industry • Food Industry • Metal Processing Industry

Innovative Cleaning Technology

The WTS-K Tunnel Washing Machines are designed as engineering marvels to deliver superior cleaning results, ideal for processes like pre-paint surface preparation, oil, and chip removal. By combining advanced technology with an efficiency and safety-focused approach, the WTS-K Series is the best solution for your high-volume industrial cleaning needs.

Optimize your production processes and elevate your cleaning standards; innovation and efficiency come together with the WTS-K Series!